If manufacturing is the gatekeeper to success in the cell and gene therapy space, it’s not surprising that the topic regularly comes up when industry leaders come together to discuss the future or to tackle the challenges we face in commercializing cell and gene therapies (CGTs).

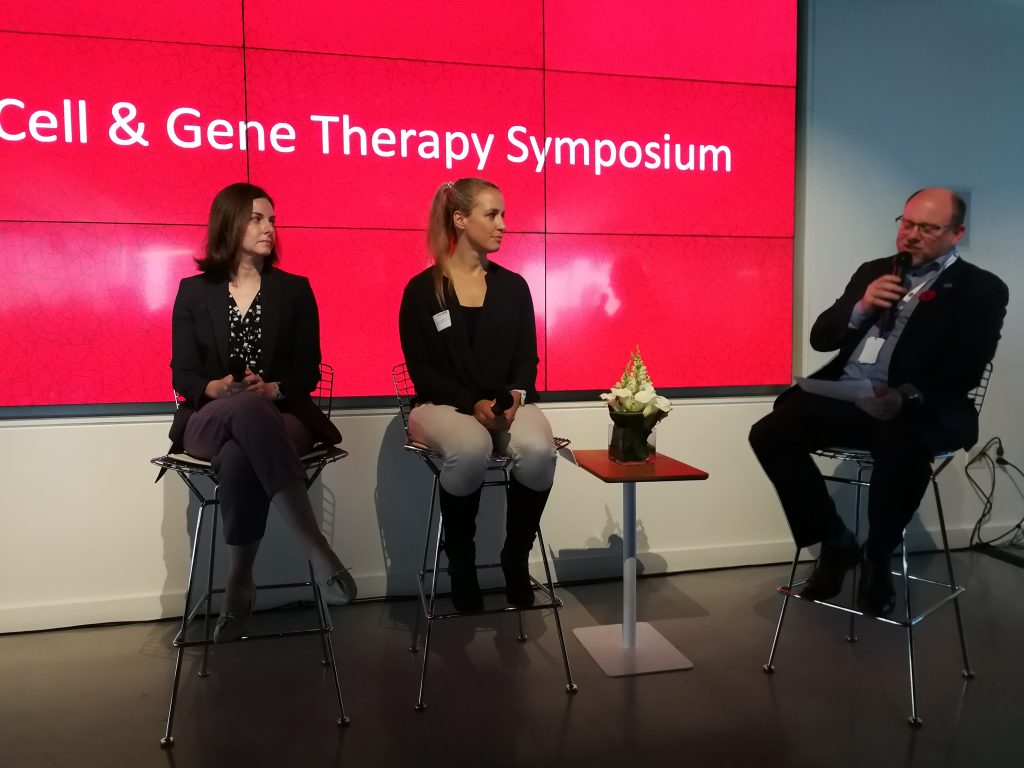

Such was the case earlier this month at the Cell and Gene Therapy Symposium: Advancing the next generation of therapies with the potential to change the trajectory of human health. Hosted by Johnson & Johnson Innovation – JLABS @ Toronto – and CCRM, the at capacity, in-person event featured a keynote talk from Bruce Levine, University of Pennsylvania, a fireside chat, panels and an innovation company showcase. We heard from academics, company executives, hospital researchers and venture capitalists. (I live tweeted from @msstaceyerin if you’d like to read highlights from the other talks and panels at the event. Scroll down to November 2,2022.)

In the afternoon there was a panel on Next Generation Manufacturing, featuring Anthony Davies, Dark Horse Consulting, John Knighton, Janssen, Lise Munsie, CCRM, and Emily Titus, Notch Therapeutics. CCRM’s Michael May was the moderator.

How did the panelists react to the statement above about manufacturing, in a question posed by Dr. May? John Knighton was in whole-hearted agreement that “it’s critical” and Anthony Davies said it has always been important, but there hasn’t been enough evolution (in equipment or processes) in the field, and we won’t see more progress until there is strong commercial pressure. Emily Titus, an early CCRM hire who moved to Notch Therapeutics following its incubation at CCRM, reminded us that induced pluripotent stem cell (iPSC) manufacturing didn’t exist 10 years ago and, when it started to appear in the industry, there was no standardization between companies. She credits Vancouver-based STEMCELL Technologies for developing customized reagents and says she’s seen a great deal of innovation in the last decade. Lise Munsie agreed that solution providers have innovated with more options for researchers. Dr. Munsie said that CCRM is looking to scale up in fully closed systems in the future. (The advantage being a controlled environment that provides optimal conditions for cell growth or differentiation, and a reduction in manual labour, which removes the human error factor.)

In response to the question, “where is supply and demand going?” we heard that CMO capacity has increased a lot (thanks, in part, to COVID-19). Also, that companies have been selling their manufacturing operations recently, which could be a reflection of economic conditions or the risk that is inherent in building in-house manufacturing operations prematurely. Dr. Davies thinks there is more viral vector capacity coming online and he’s watching for data that the bottleneck has been solved, and notes that contract development and manufacturing organizations (CDMOs) are scooping up these facilities from developers. Dr. Titus stated that Notch will have to work with CMOs and, even as a startup, they have a lot of manufacturing needs. She considers her company to be a “small fish” to a CDMO so capacity will be an issue. (With more than 2,000 clinical trials ongoing this year at the end of Q2, and regulatory decisions expected for 15 therapies in 2023, according to the Alliance for Regenerative Medicine, demand for CDMOs will be high. Industry Standard Research states that innovators, on average, need three CDMOs to meet their manufacturing needs and this number is expected to grow to four in the next five years.)

The panel also responded to the question “what can trip up companies?” Mr. Knighton said you can’t de-risk everything for your product, but you should be thinking about the future as you prepare to file. (That’s a good point as it can be costly to make changes late in the development process. At CCRM we advise our clients that if you need to make any significant changes for regulatory reasons, doing this late in development will typically require additional preclinical or even clinical data to support it. If you think about your end point before you even initiate your preclinical animal studies, this type of change can be made with a smaller and easier-to-collect dataset.) Dr. Munsie explained that moving iPSCs into Good Manufacturing Practices (GMP) is challenging as there is a gap in clinical-grade cell types. Cell lines are not always available for commercial purposes. While it’s possible to produce the cell lines safely, there needs to be collaboration to solve the early process challenges and it requires Freedom to Operate (the ability to use or commercialize a product or process without infringing another party’s IP rights or patents). Dr. Munsie said that consultants are encouraging companies to use GMP-grade cells and Dr. Davies agreed. He said that companies are growing their own cell lines because they are difficult to obtain and, while it’s more challenging to develop your own cell lines, it solves the access issue. Mr. Knighton advised to “document the cell-line history.”

Manufacturing is an important topic right now as companies race to commercialize their products. Coincidentally, a week after this event took place 3M hosted a full-day symposium, also in Toronto, featuring talks on bioprocessing and biomanufacturing. (You can see the program here and read my tweets if you scroll down to November 9th.) Don’t be surprised if I revisit the topic again soon: Advanced Therapies Week is less than two months away.

Stacey Johnson

Latest posts by Stacey Johnson (see all)

- Right Turn: Top 10 blogs from 2025 - January 9, 2026

- Right Turn: Season’s greetings and upcoming event - December 25, 2025

- Right Turn: Stem cell supplements: A growing market with growing risks - December 19, 2025

Comments