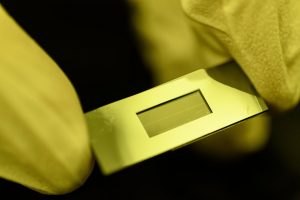

A microfluidic exchanger

Erika Siren lives in Vancouver, British Columbia where she is currently a Ph.D Candidate in the University of British Columbia’s Department of Chemistry. Under the supervision of Dr. Jayachandran Kizhakkedathu, Erika develops biomaterials that can be used to manipulate the immune system. Away from the bench, Erika has a keen interest in the challenges that face the commercialization, policy development and public perception of therapies in regenerative medicine. Connect with Erika on Linkedin here.

As cell therapies experience their market debut around the world, pharmaceutical companies and regulatory bodies have become increasingly concerned over how to ensure product quality is consistent across international manufacturing facilities. In response, there’s been pressure on researchers to develop precise quality control strategies that can more accurately monitor these therapies during the manufacturing stage.

In a “small” step toward ensuring the consistent manufacture of living cell therapies, researchers at the Georgia Institute of Technology have developed a miniaturized, online monitor that is capable of tracking cell quality with unprecedented precision.

In a pursuit led by Drs. Andrei Fedorov and Robert Guldberg (Dr. Guldberg is now at the University of Oregon), scientists developed a microfluidic platform that enabled the use of label-free, highly sensitive electrospray ionization mass spectrometry (ESI-MS) for continuous quality monitoring in large-scale bioreactors.

Precision manufacturing is no small feat for living therapies. Once harvested from the donor, the cells continue to respond to environmental and temporal changes during the manufacturing process. While a certain amount of variability is unavoidable in living cell therapies, gross changes during manufacturing could have a major impact on the potency – and safety – of the final product.

On an international scale, many believe the best bet to avoid this outcome is the harmonization of manufacturing processes across facilities to maintain product consistency. Within large-scale bioreactors, consistent manufacturing is verified by monitoring the critical quality attributes (CQA) of cell batches. CQAs are often assessed in real time with monitors that continuously detect various parameters and adjust bioreactor conditions accordingly through online feedback control.

Continuous sampling is essential in bioreactors to maintain the narrow environment in which cells are healthy. Many of these parameters, however (i.e. temperature, pH), offer limited information on how the cells are actually behaving, making it difficult to truly measure variability between batches. While other methods have been developed to more precisely characterize cell populations, lengthy processing times make most unsuitable for continuous, online monitoring.

While ESI-MS has proved to be a powerful tool in the precise characterization of complex biological samples, it’s utility as an online monitoring device has been hindered by the need for rigorous sample purification. The high concentrations of inorganic salts present in cell media is infamous for its ability to weaken ESI-MS sensitivity, and is considered one of the biggest culprits in slowing down processing times for biological applications. In a purification process that can take hours to days, ESI-MS was once considered an impossible candidate as a continuous, online monitor in cell manufacturing. Detailed in the September issue of Biotechnology and Bioengineering, the researchers were able to overcome this limitation by using microfluidic technology to develop a Dynamic Mass Spectrometry Probe (DMSP) that dramatically expedites ESI-MS sample preparation.

No larger than your fingertip, the tiny DSMP works as a “mass exchanger,” pushing biological samples through a size-selective membrane where tiny nanoscale pores selectively, and rapidly, filter out salts. These pores were able to remove as much as 99 percent of the smaller salt molecules in biological samples, while retaining 80 percent of the larger biomolecules. The biomolecules are then treated with additives within the device to enhance target detectability before ESI-MS analysis, enabling the simultaneous detection of multiple biomolecules in as little as a nanolitre of sample.

The simple, yet powerful DMSP design can process samples in less than a minute, finally making ESI-MS feasible for real-time monitoring. Moreover, employing ESI-MS will finally enable the high fidelity, continuous monitoring of multiple biomolecules that can more precisely reflect changes in cell behavior.

The low-cost device can also be mass-produced and easily integrated into current manufacturing processes, giving the DMSP broad applicability across manufacturing sites. Researchers are still determining what biomolecules to profile as CQAs before integrating the DMSP device into bioreactors.

This is some of the first published work to come out of the NSF-funded Center for Cell Manufacturing Technologies (CMaT) (CCRM is a partner). CMaT is a multi-institute initiative dedicated to the development of robust, scalable, low cost biomanufacturing of high-quality therapeutic cells.

With global interest in living cell therapies, it is imperative that existing manufacturing strategies evolve to ensure worldwide product quality. Technologies like the DSMP are an excellent example of using simple, well-designed tools that can rapidly “clean-up” biological samples to harness the power of old analytical techniques and solve new challenges in bioprocessing.

Guest

Latest posts by Guest (see all)

- Regenerative immunotherapy: Hope for chronic autoimmune diseases - September 16, 2025

- Canada’s regenerative revolution: Why AI is the catalyst - September 4, 2025

- Summer by Design: A launchpad for future entrepreneurs and industry scientists - August 14, 2025

Comments